Unitsky String Technologies Inc. Introduces Energy-Independent Types of Transport Retardation

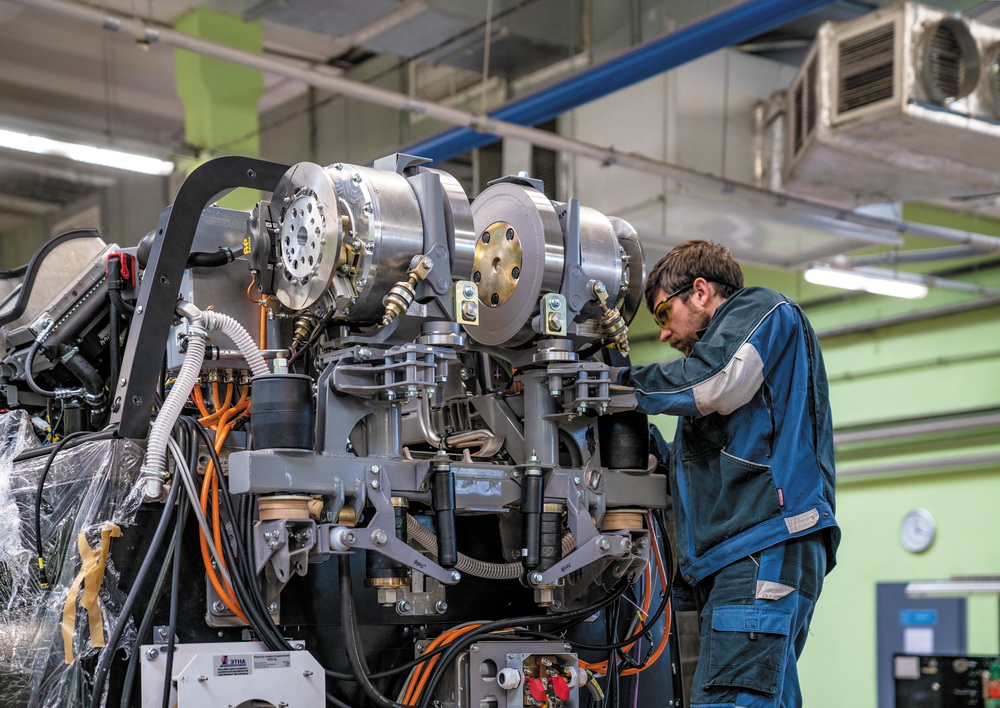

Current brake systems require continuous maintenance, repair and replacement of consumables because of friction surfaces, which makes their improvement relevant over time. UST transport systems will be equipped with eddy-current retarders. Why is this component innovative and what advantages does it bring to string transport? Figure out with Pavel Valkovich, Chief of Power Engineering Office in Unitsky String Technologies Inc.

What is eddy-current retardation?

First of all, this is a method to decelerate vehicles whereby braking force emerges due to interaction of magnetic fields. How does it work? Resistance that stops a moving object represents an electromagnetic force between a magnet and the nearest current-carrying object (tire) which are moving relative to each other. Currents in the conductor (tire) are electromagnetically induced to form an inherent magnetic field. Such a design does not assume a mechanical contact, which prevents both the brake system and the vehicle from wearing. Its main feature is energy independence as this design uses permanent magnets which eliminate the need for electric supply. This system is always operable and efficient regardless of vehicle speed and state of the rail surface condition. We can utilize it, for example, as an emergency retarder on stub tracks or as a working vehicle retarder. Simply speaking, this is a secondary braking system which helps to decelerate vehicles, thus reducing abrasion of regular brakes.

The retarder was developed in three stages. Originally, we took tests to determine optimal layout for further designing. Many variants can be made up but the most efficient one is always an issue. Our purpose was to reach maximum braking torque with a minimum number of magnets. So far, we have developed two variants of prototypes with different braking torques.

It is important to understand that this is not a braking device but a retarder. Braking torque in this mechanism occurs when the tire and magnets have different speed. Braking torque increases with speed. We call ourselves an innovative company since we apply complex solutions for transport systems. In contrast to our solution, rail or motor vehicles, for example, are equipped with electromagnetic retarders (retarders) which cannot operate without electric supply.

What are the advantages of this complex?

1. Energy independence. As we said before, the eddy-current retarder on permanent magnets is an energy-independent solution.

2. Long life time. Modern braking systems are most reliable but not perpetual. Many of their components are so called consumables that require frequent replacement. Meanwhile, the life time of modern permanent magnets is at least 25 years.

3. Weather resistance. The retarder is immune to freezing, overheating or excessive moisture not speaking about safety since it does not depend on the state of the rail surface compared to motor vehicles which collide most frequently in winter. Braking distance on an icy surface increases by several times and cars skid off, reverse or turn over.

4. Sustainability. It does not pose any threat to the environment for it is designed without wear parts. For instance, previous cars were equipped with shoes partially made of asbestos containing materials which are considered cancerogenic and environmentally hazardous.

5. Silence. When a car stops abruptly, friction of brake shoes initiates an unpleasant sound and heat from wheels. The eddy-current retardation does not assume a physical contact that can induce noise.

6. Functional parameters are observed without a mechanical contact. This allows a fundamentally new set of parameters for brake units of cars and mechanisms which are impossible to obtain following a simply mechanical approach. Constructively, retarders can be implemented with different braking torque magnification factors. For example, if you need to trigger emergency eddy-current braking on a stub track, it can be adjusted to maximum and minimum force.

Maximum effect at minimum cost — this is the basic principle of the new concept of slowing down string transport, which should be the same for any other transport system. Unfortunately, this is not the case, and modern transport works in exactly the opposite logic. The service life is specially shortened in the interests of manufacturing concerns, energy consumption is consistently maintained at a high level beneficial to hydrocarbon producers and processors, and the road infrastructure requires constant expansion due to the incessant growth in the number of vehicles, most of which occupy urban space. This model demonstrates its impasse. UST technology looks absolutely preferable against this background. Now that its efficiency and safety have been confirmed in practice, we can be sure that this type of transport is the future.

More news

Blog

28 September 2023

Elevated Transport Communication: How uST Routes Can Connect Different Coastal Areas

uST Solutions can be used to organize transport communication not only above the ground, but also above the water barriers and swampy areas. uST routes can connect city areas or settlements located on different banks.

Interviews

15 November 2023

At what stage is the work on the UST Inc. project for the Leningrad region?

These and other questions were answered by Evgeny Petrov, the Deputy General Director of UST Inc. in an interview with RZD-Partner.

Interviews

22 July 2022

New Interview: Anatoli Unitsky on the Implementation of Projects in the UAE and Belarus

In a new interview, Anatoli Unitsky talks about what Unitsky String Technologies Inc. has done, how the work is progressing at the test and demonstration center in the United Arab Emirates and at the head office in Belarus.