The Innovative Transport Journal Has Published the Article About the Prospects of String Transport for Cargo Transportation

The cargo industry has now exhausted its development possibilities and needs breakthrough solutions. Energy efficiency, environmental friendliness, cost-effectiveness, accessibility, automation, construction speed and low operating costs are some of the key indicators that need to be improved.

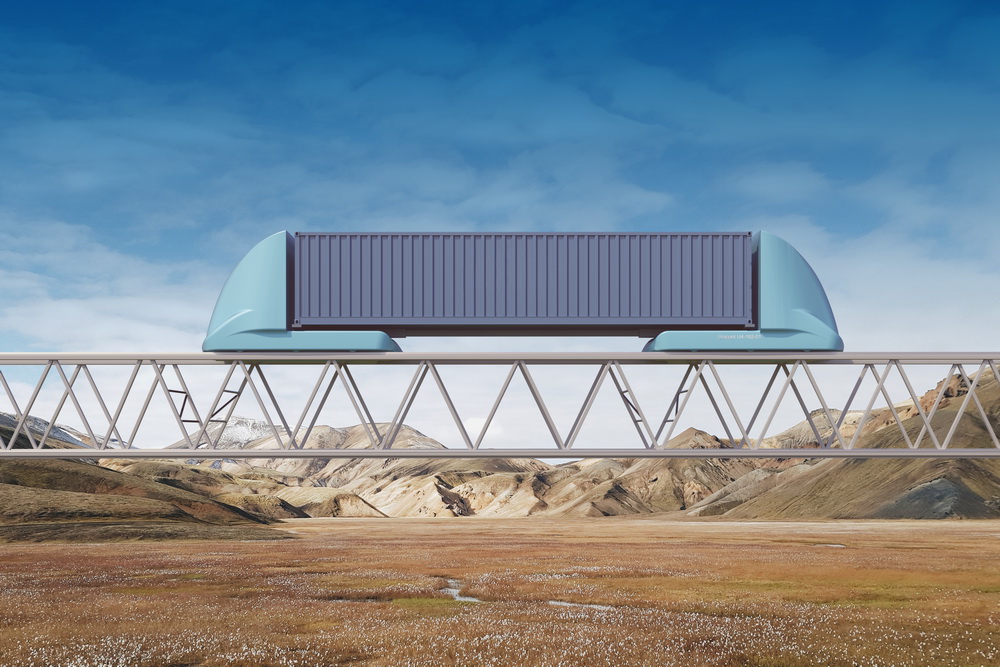

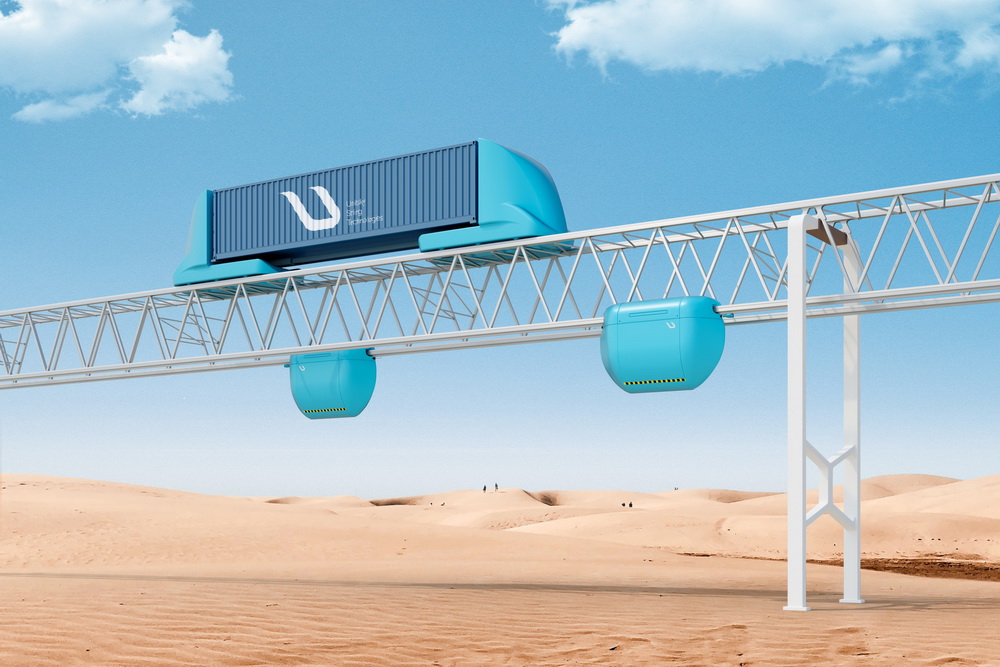

As the authors pointed out, Unitsky's String Transport (UST), recognized as innovative by the Ministry of Transport of Russia in 2017, is able to become a promising mode of transport that solves the above issues, where unmanned mounted and suspended vehicles with steel wheels move due to electric traction along a continuous, prestressed string rail track structure.

The UST cargo complexes can be used for the transportation of bulk (ore, coal, rubble, gravel, sand), tanker (oil and petroleum products – chemical products, liquefied gases, high-quality natural drinking water), unit (wood and timber, steel rentals, containers), and special (household and industrial waste) cargoes.

The maximum technology effectiveness is demonstrated by the use of string cargo transport in regions with complex topography, water barriers, large number of transmission lines, agricultural land, mass developments, and other obstacles. The routes are paved by the shortest way, making the delivery process much cheaper. Such roads can be used in regions with all kinds of weather conditions.

As the edition noticed, string transport is high-environmentally friendly as it uses electricity as energy source, not diesel or petrol that pollutes the environment. The steel wheel – steel rail pair with high aerodynamic qualities of the rolling stock provides for low energy consumption. Minimum volume of earthwork and excavation is required for the construction of a rail-wire overpass, which ensures high terra-efficiency.

String rails are resistant to acts of vandalism and terrorism, as well as to adverse weather and climate conditions, unlike, for example, cable roads, where a carrier rope is unprotected and its break can lead not only to material damage, but also to human casualties, especially if the road passes over built-up areas or transport routes.

String transport provides complete automation and remote control of loading and unloading operations without the direct presence of people in potentially hazardous areas. Maintenance of the system does not require the construction of separate land roads. Delivery of personnel and items for repair and maintenance is carried out directly along the route itself.

The basic layout of the track structure of the Unitsky String Technologies Inc. cargo complex implies that the main loads from the superstructure and rolling stock are transferred to the anchor supports – this allows to make intermediate supports light, cheap and easy to install without loss of strength and load capacity.

As the authors pointed out, cargo systems can be constructed under different climatic conditions and on different landscapes, including mountains and the sea shelf.

Now the work of the Unitsky String Technologies Inc. cargo transport complex is provided by the following vehicles: unicont, unitrack, and unitrans.

Read the details on the link.

More news

Interviews

26 November 2021

Engineers of Unitsky String Technologies Inc. Measured Temperature on Track Structures of the EcoTechnoPark

The head of Transport Overpass Design Office Vyacheslav Babushkin shared teh purposes and outcomes of the work.

Opinion

3 August 2022

The Expert Opinion of General Director of Unitsky String Technologies Inc. Was Published in Forbes

One of the most authoritative financial and economic publications in the world has published an expert opinion of General Director of Unitsky String Technologies Inc. Nadezhda Kosareva. The article raises the problem of air pollution and discusses ways to solve it.

Blog

16 September 2022

How Can Unitsky String Technologies Inc. Transform the World of Maritime Shipping?

There are various applications for UST Inc.'s transport and infrastructure complexes, and one of them is maritime shipping. The use of string-rail overpass makes it possible to build seaports at some distance from the shore. This will exclude the work and expenditures that are necessary when constructing seaports near land.